Corrosion Technologies

Corrosion Technologies

Our Zerust Oil & Gas technologies have been successfully implemented across refineries, oil rigs, and tank farms around the world. By combining our proprietary Zerust inhibitor formulations with some of the traditional corrosion mitigation methods in use today (cathodic protection, coatings, etc.), our advanced technology yields several unique and innovative solutions that counter expensive corrosion problems.

Zerust corrosion engineers go beyond VCI technology by offering a comprehensive system called Integrated Corrosion Technologies (“ICT”). Our trained professionals will help you pick the right VCI solution for your corrosion need.

Vapor Corrosion Inhibitors (VCIs) and Soluble Corrosion Inhibitors (SCIs).

Zerust Oil & Gas is a world leader in protecting bare metals from corrosion using Vapor Corrosion Inhibitors (VCIs) and Soluble Corrosion Inhibitors (SCIs).

VCIs and SCIs can be used to protect metal parts from corrosion without the need for greases or painting.

Zerust VCIs and SCIs have been effectively and safely used to protect valuable parts and equipment.

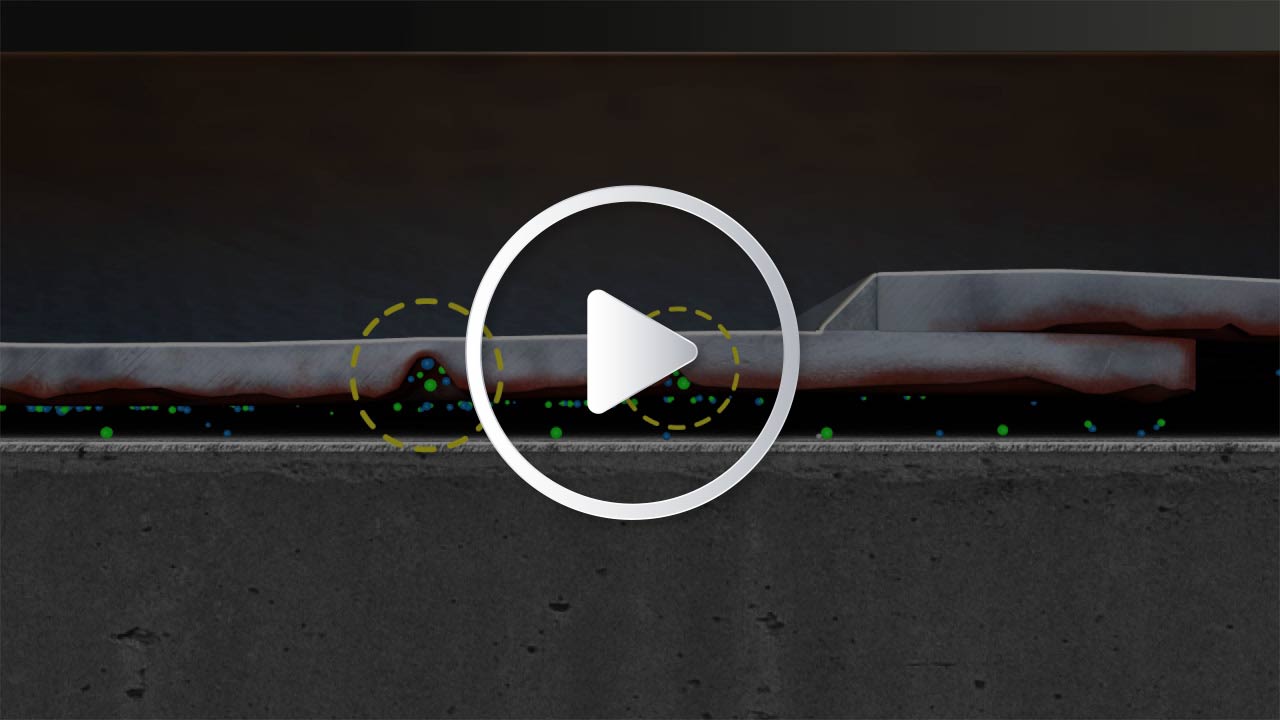

How do VCIs and SCIs work? Click Here to watch a video to find out.

Zerust Zerion® FVS

Zerust Zerion® FVS is a highly cost-effective corrosion mitigation solution for difficult to protect spaces. Some key applications include soil side bottoms of aboveground storage tanks, tank pontoons, protection of voids/enclosures, large equipment preservation, pipeline layup, pipeline casing protection, hydrostatic testing, offshore risers, long-term preservation/mothballing and more.

Zerion FVS’s two forms of protection:

- Vapor Corrosion Inhibitors (VCIs) to protect the interiors of “air space” voids and exposed metal surfaces on welded joints, in crevices, at coating holidays, etc.

- Soluble Corrosion Inhibitors (SCIs) that mitigate corrosion from moisture accumulation or the ingress of water.

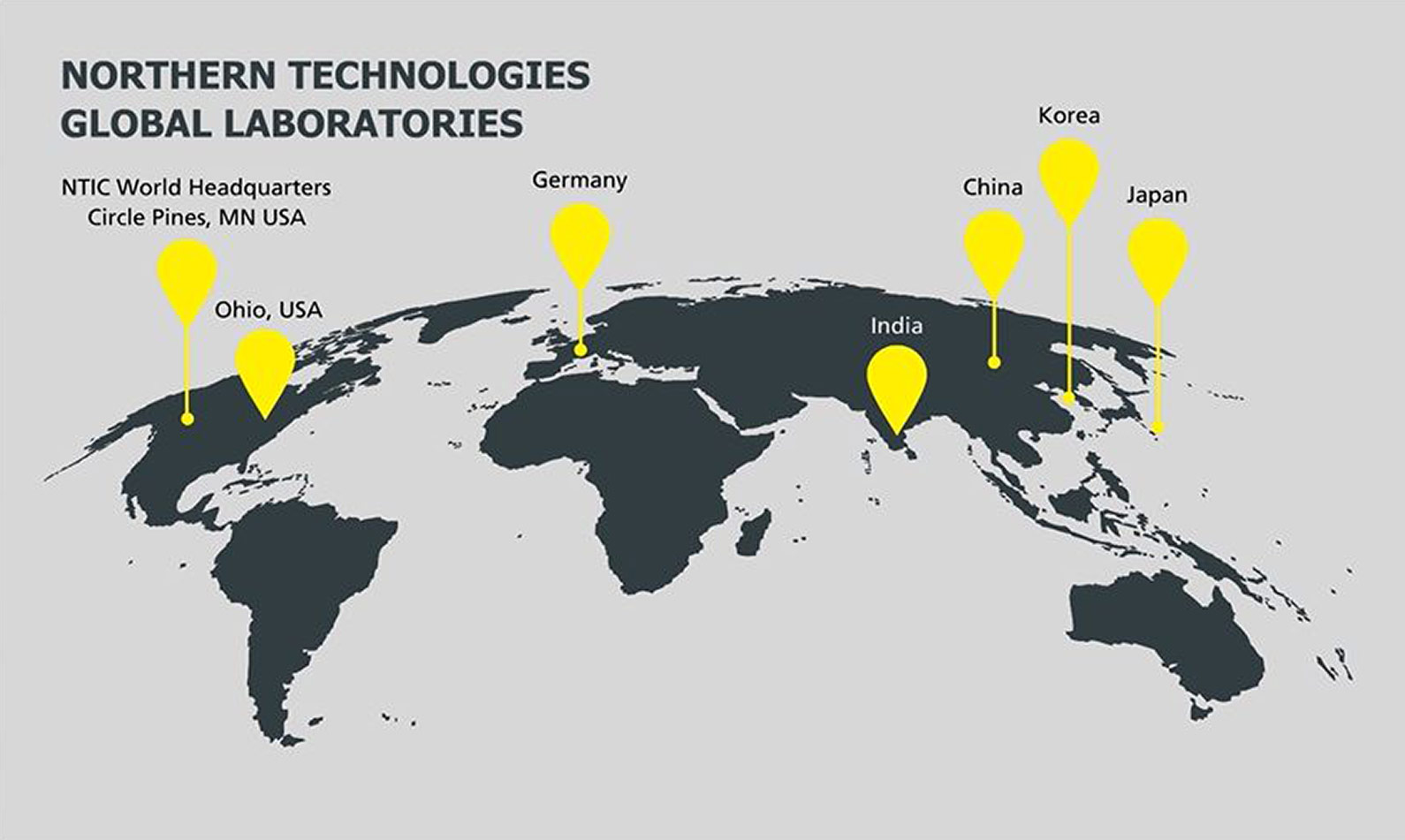

Laboratories and Test Facilities Across the Globe (R&D)

Field trials and rigorous R&D lab testing are conducted to continuously evaluate our corrosion protection solutions. Our laboratory personnel leverage specialized equipment to conduct accelerated testing in various corrosive environments relevant to the Oil & Gas industry, including those with traces of Hydrogen Sulfide (H2S), Sulfur Dioxide (SO2) and Carbon Dioxide (CO2).

The Zerust® Oil & Gas team has state of the art laboratory facilities in Beachwood, Ohio (USA) and in Circle Pines, Minnesota (USA) that are used for primary corrosion research, product development, and joint R&D with our clients and analysis of field test data. Zerust® Oil & Gas also has access to worldwide regional Zerust®/Excor® technical support centers.