Types of Casing Fillers - Advantages and Disadvantages

Casing fillers are used to prevent corrosion on carrier pipelines. NACE SP0200-2014 defines casing fillers as a product placed in the annular space between the carrier pipe and casing pipe to inhibit corrosion and assist in preventing the ingress of electrolyte.

The oil and gas corrosion prevention industry has used and adopted several different casing filler materials, and some of them have been obsolete due to the elevated risk of corrosion.

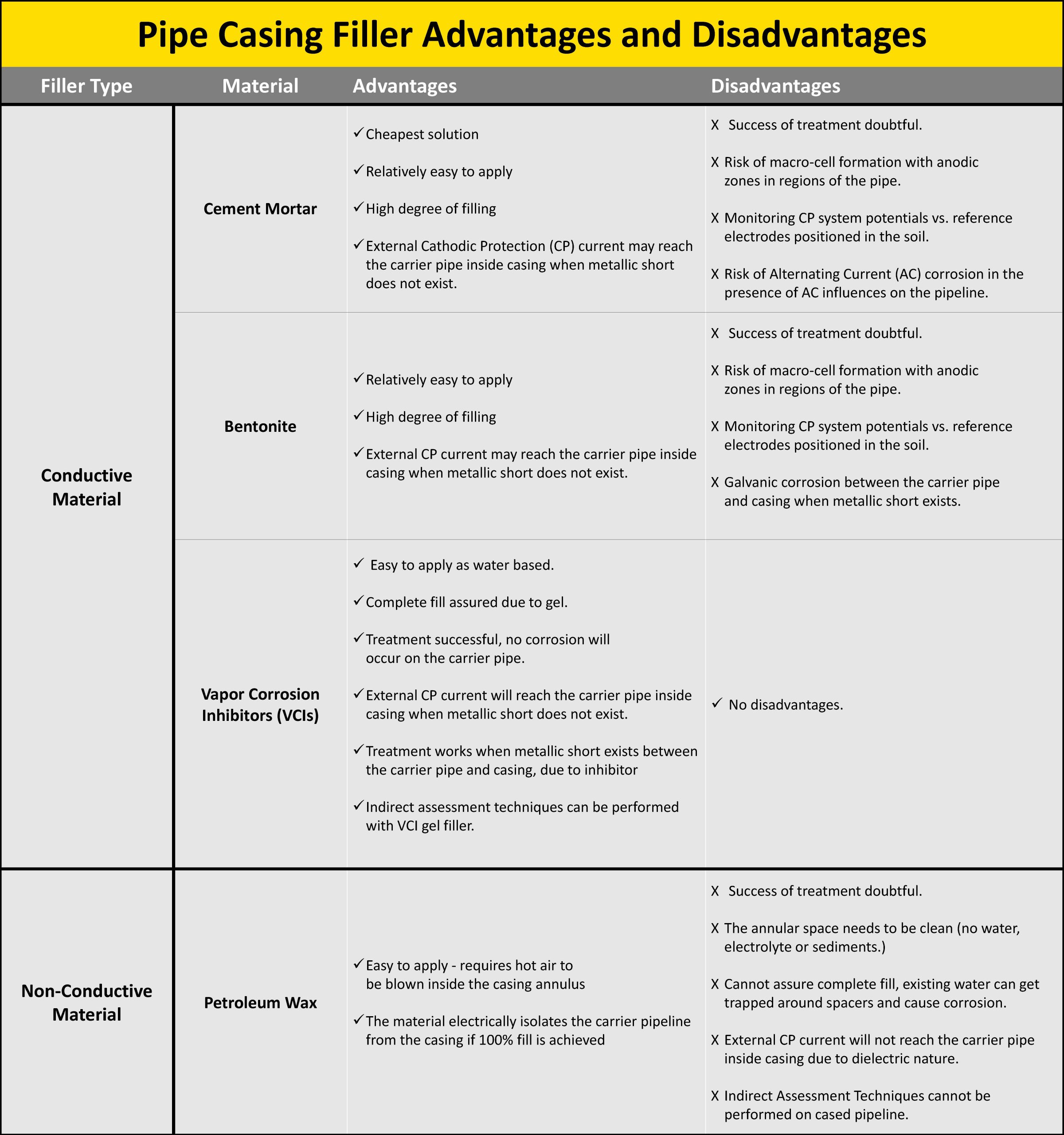

Below is an overview of common fillers adopted, their material composition, and the advantages and disadvantages associated with each casing filler.

Cathodic Protection (CP) has also been used inside the casings using a zinc ribbon anode to protect the carrier pipe. However, this CP technique has not been successful due to the below reasons:

- Zinc Ribbon relies on rain water to act as an electrolyte

- Zinc passivates over time and stops providing CP current

- Difficult to install, and potential to create metallic short between the carrier and casing pipe

VCI gel filler is the state-of-the-art technique to use for the underlying reasons:

- The high pH = 9.5 of VCI gel and inhibitor mechanism aides in significant reduction in corrosion rates of steel pipeline in contact with VCI gel electrolytes.

- For electrolytic couple scenarios, VCI gel solutions provide a conductive path for CP current to the holidays. Inhibitor action of the VCIs provide background corrosion inhibition.

- For metallic short scenarios, VCI gel solutions provide background corrosion inhibition and a conductive path for CP current to the holidays in case of high resistance shorts.

- If there is no metallic short, the use of VCI gel in the annulus space eases the use of indirect assessment techniques required during periodic reassessments. In case of metallic short, the VCI gel provides protection to the carrier pipe and corrosion mitigation can be monitored with ILI techniques.

For more information on the advantages of using VCI Gel filler for pipe casings, click here.