Determining Corrosion Delivery Method for Tank Bottom Protection

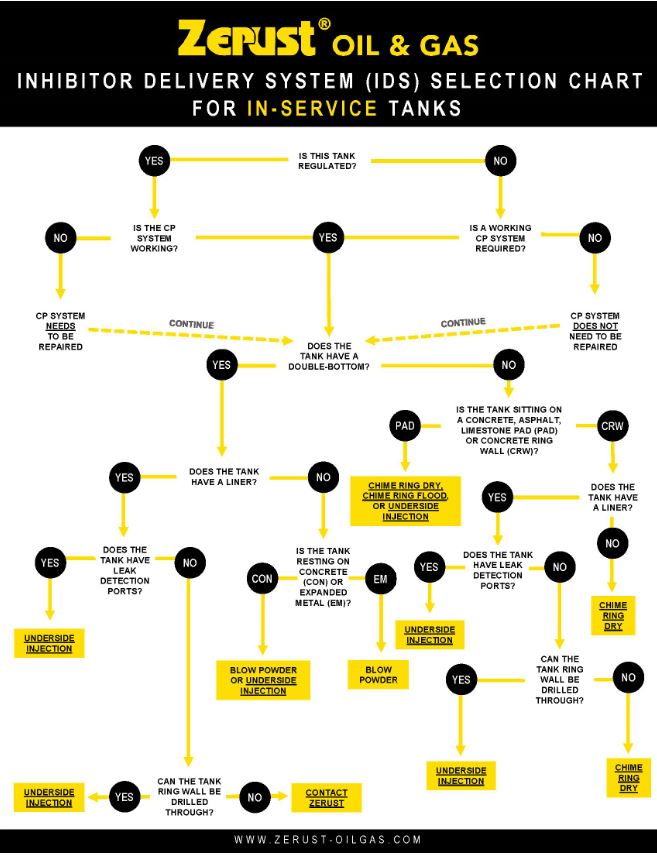

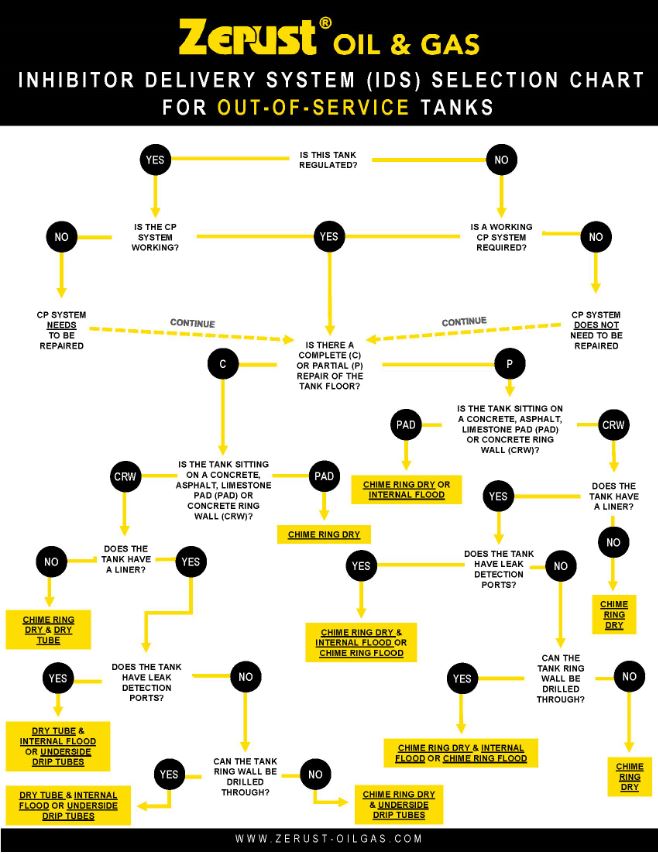

Zerust Tank Flow Charts for Selecting Inhibitor Delivery System (IDS)

Hello, my name is Amanda Szwed and I am the Project Manager for Zerust Oil & Gas, coordinating all of our implementation projects since 2015 out of our Beachwood office in Ohio.

As you can imagine, there are different responsibilities and tasks that I manage or delegate to ensure that our projects are fully, and completely, implemented. Most of the time, however, I work with our clients and our sales teams to ensure that the right solution is selected.

Every proposal for our Tank Bottom corrosion mitigation solution starts with custom-design work that includes a thorough evaluation of the construction details for a targeted asset. I often get a lot of questions during the proposal stage of a project regarding what information we require for determining which of our inhibitor delivery systems (IDS) is the most appropriate for a given asset.

Zerust Oil & Gas Inhibitor Delivery Systems (IDS)

These systems were designed to allow for application of our corrosion inhibitor compound to a variety of different environments and construction types. To help determine which system is the most applicable for a given vessel, we’ve created two (2) user-friendly flow charts that highlight the most common key design elements for assets that are of the utmost importance for our design team.

Zerust offers a variety of Tank IDS options that include:

• Underside Injection IDS

• Chime Ring IDS

• Internal Flood IDS

• Dry Tube IDS

• Drip Tube IDS

Tank IDS Selection Flow Charts

Tank IDS selection flow charts shown below are specific to Aboveground Storage Tanks (ASTs) and are separated based on operating status of the targeted asset (in or out-of-service).

How to Use the Zerust Tank IDS Flow Charts

The Tank IDS Flow Charts are simple to use. Start by answering the first question and depending on the answer, either go down and right or down and left to answer the next question. Eventually, you will end up at one of the five Zerust Tank IDS options outlined before.

Explanation of Select Tank IDS Flow Chart Questions

Below is a more detailed chart review and explanation for the questions asked in the in-service tank flow chart (Figure 1).

Underside Drip Tube IDS Double-Bottom

Underside Injection IDS – Tank has Liner

Underside Drip Tube IDS – Port & Probe

- Does the Tank have a Double-Bottom?

- A double-bottom design means that a new floor has been installed atop the original floor, with a foundation media introduced between the floors.

- Does the Tank have a Liner?

- This question is important because, without a liner or similar design, introduction of corrosion inhibitor compound can be limited to a dry approach (i.e. application via corrosion inhibitor sleeves around the tank annulus).

- Depending on the condition of the original floor, retention of a corrosion inhibitor wet solution may still be possible, that’s why we’d request further details via available schematics, MFLs and other reports.

- “Does the tank have leak detection ports?”

- This question can also be read as “Does the tank have ports extending through the dead shell between the floors that can be used for corrosion solution injection?” If it does, or if the client is willing to install these ports, most often, we can apply our corrosion inhibitor compound via injection of a corrosion inhibitor solution.

- This is done via an Underside Injection IDS where corrosion inhibitor compound is mixed with clean, potable water in a mixing tank and pumped via the existing or installed ports using a submersible pump, garden hoses, manifolds, etc.

- If the tank doesn’t have ports through the dead shell and the client isn’t willing to install these ports, we often ask for further information that can help us decide how else to apply corrosion inhibitor.

Additional Questions for IDS Method Selection:

The Tank IDS Flow Charts offer a good starting point and provide a brief overview of the Zerust Oil & Gas inhibitor delivery systems and our options for inhibitor application. However, the charts are contingent on the basics of asset’s construction and operation design.

Additional questions, may be posed by our team to ensure the most effective IDS method is selected for the client’s asset. Listed below are a few questions that may be asked.

- Will the asset be taken out-of-service at any point in the near future?

- Where are the primary areas of corrosion concern?

- This will help us determine if it’s realistic to apply our solution to target these areas with the limitations posed by the construction of the asset.

- Are there monitoring wells or other similar points of entry to the foundation media between the floors that could be used for application of a corrosion inhibitor solution?

Our Team is Here to Help

The staff at Zerust Oil & Gas are here to custom design a corrosion mitigation solution that is specific to your given asset. Contact us today to find out how we can help extend the life of your equipment.