Corrosion Under Insulation Testing of Zerust® Inhibtior Fusion (ZIF) Tape

Corrosion Under Insulation (CUI) Testing of Zerust® Inhibitor Fusion (ZIF) Tape

Background

Corrosion under insulation (CUI) is a prevalent problem affecting thermally insulated equipment across a wide variety of industries. CUI occurs through the penetration of water or moisture via condensation or external sources through the insulation of the underlying metal surface.

Fig. 1: Example of corrosion under insulation

A simple lab test was conducted to evaluate the effectiveness of Zerust® Inhibitor Fusion (ZIF) Tape for CUI. In the test described below, a comparison was made between the control panels (no corrosion protection) and the test panels (protected by ZIF Tape). To simulate CUI, the test approach was to age panels that had been sandwiched between two pieces of damp insulation. The panel assemblies were then sealed in quart jars and aged at 50°C.

Experimental

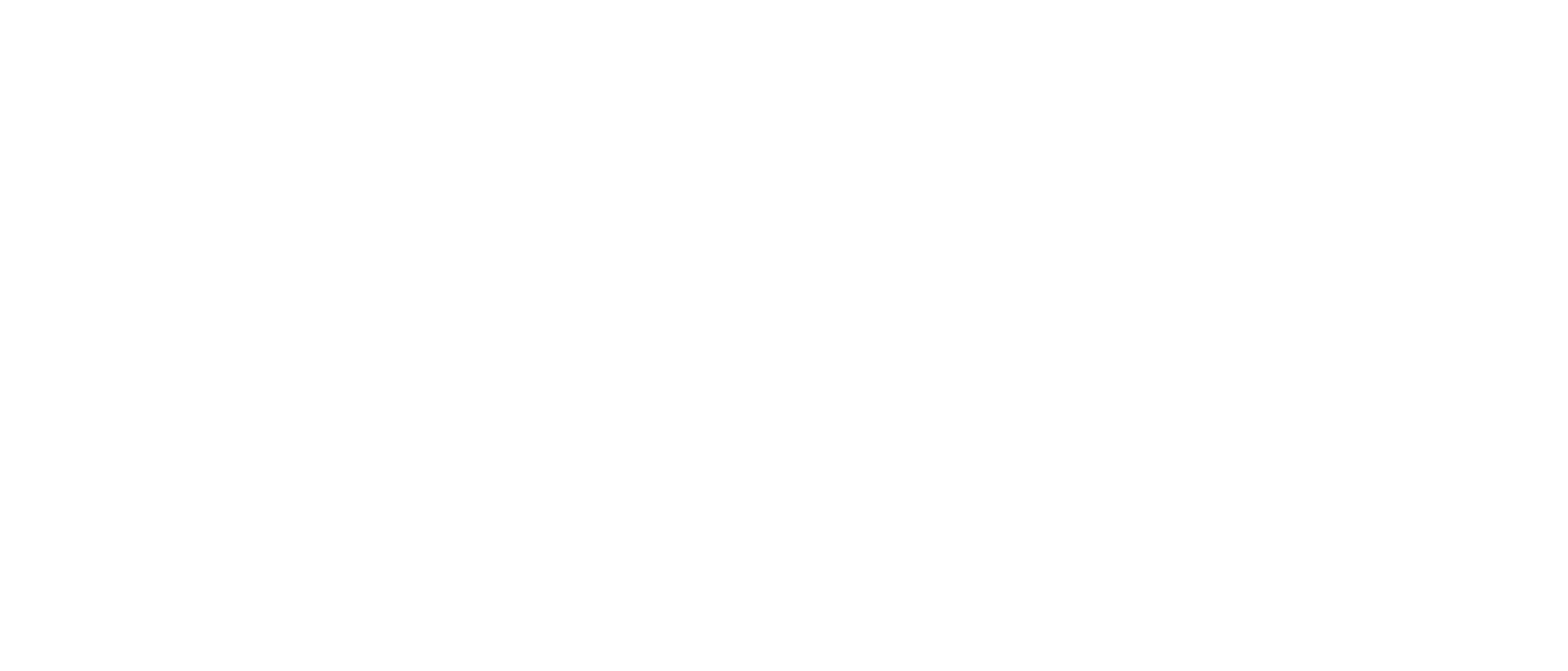

A brief outline of the experimental procedure can be found below:

- Steel panels cleaned by solvent wipe.

- Test panels were wrapped with ZIF Tape

- The panel was sandwiched between two pieces of damp insulation.

Fig. 2: Test Panel Assembly

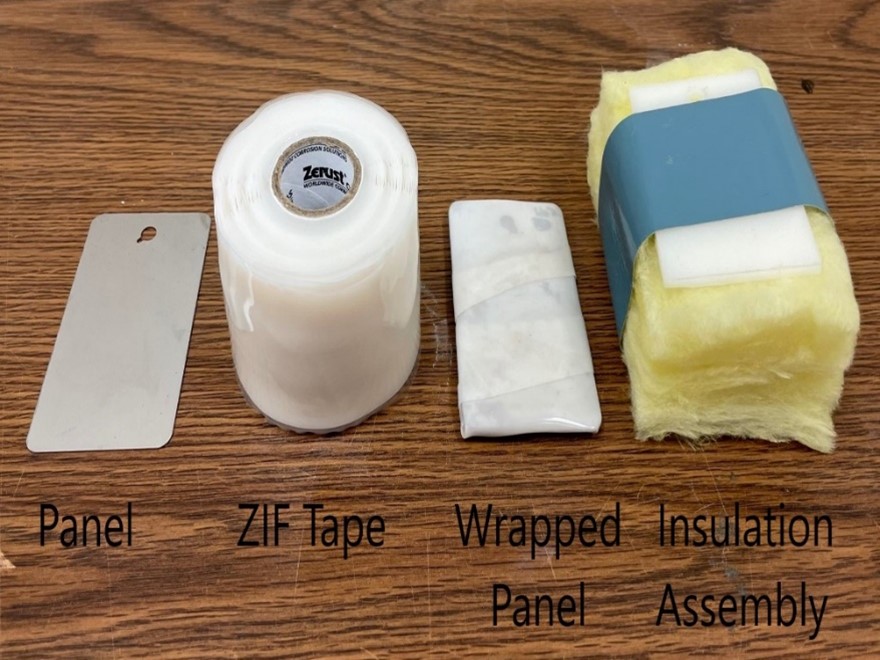

- Assembly was placed in a quart jar.

- The jar is sealed and aged at 50°C.

- Every week, water was spritzed onto the insulation to ensure continued dampness.

Fig. 3: Test Assembly

The testing was performed on two different substrates:

- Standard smooth mill test panels

- Pre-corroded panels

Panels were pulled periodically and visually inspected for qualitative evaluation.

Results & discussion

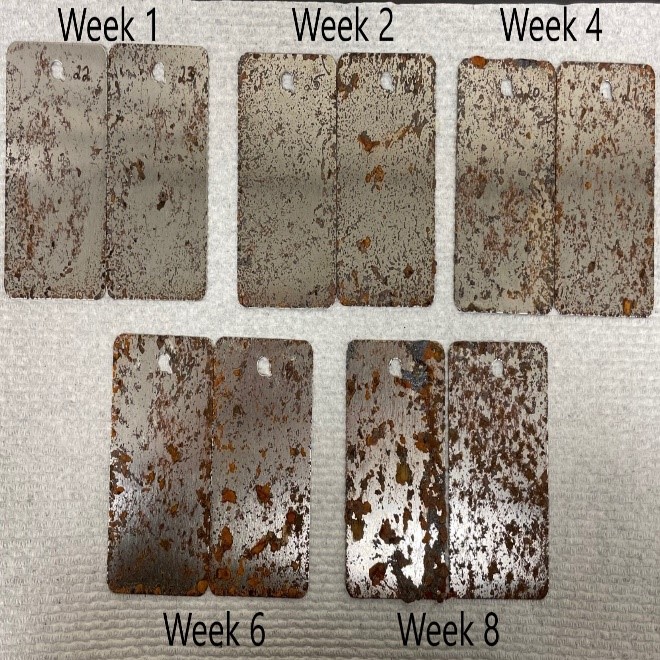

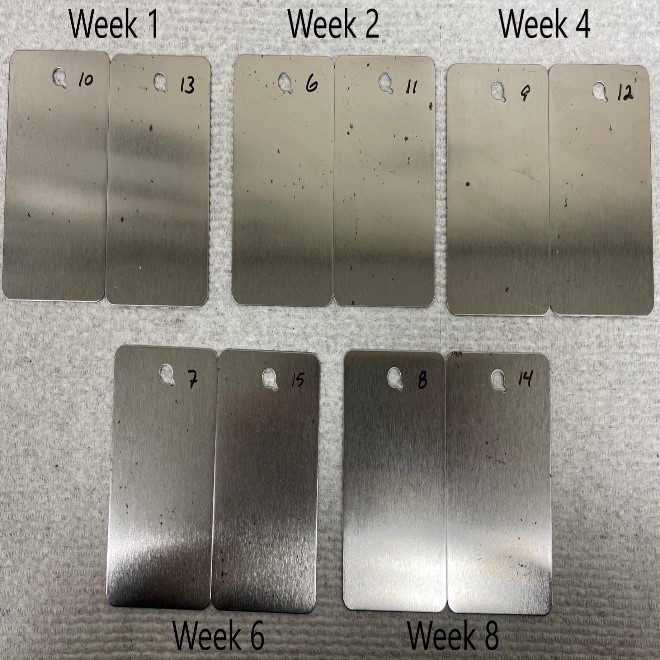

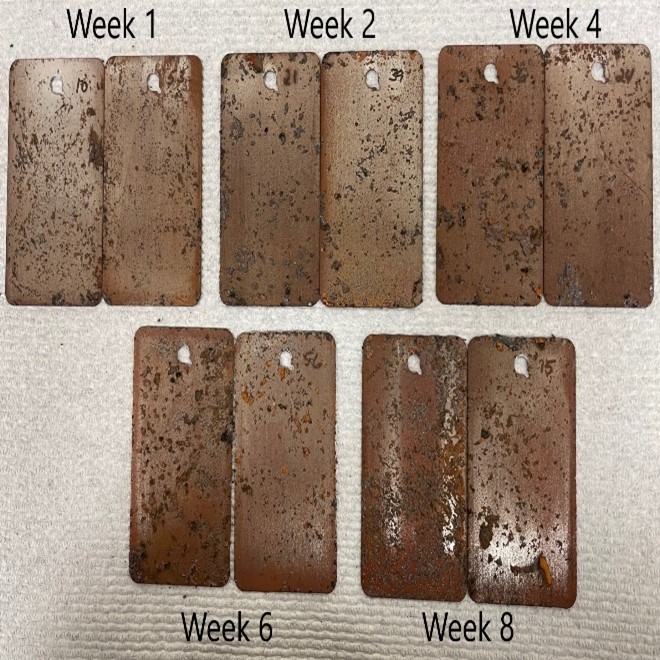

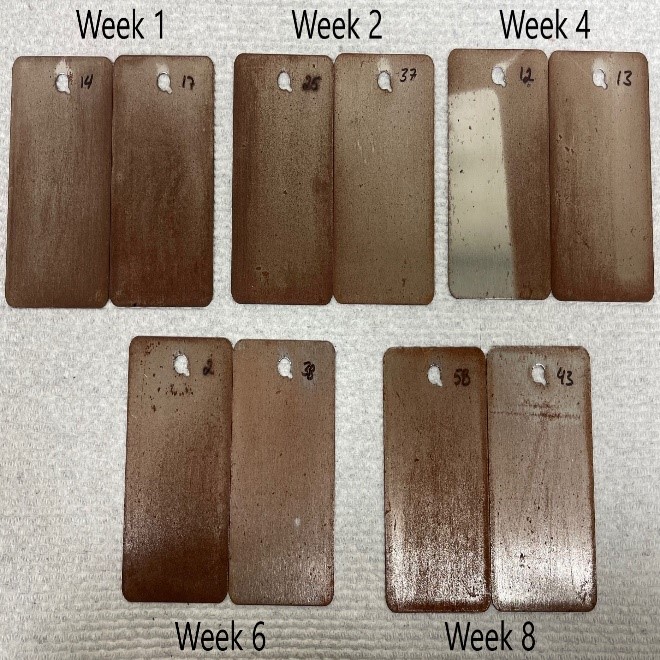

Comparison pictures of the panels at the one, two, four, six, and eight week pull dates are shown below.

1. Smooth Mill Panels

|

|

| Fig. 4: Control panels |

|

|

|

Fig. 5: Panels treated with ZIF Tape |

2. Precorroded Panels

Before performing the test, smooth mill panels were purposely corroded via exposure to an acidic environment for 24 hours.

|

|

| Fig. 6: Precorroded control panels |

|

|

|

Fig. 7: Precorroded panels stored with ZIF Tape |

For the pre-corroded panels, new, large, corrosion products continued to become apparent on the control panels while minimal new corrosion products were apparent on the test panels.

Conclusion

A clear benefit can be seen from the ZIF Tape for both the smooth mill and pre-corroded substrates. As can be seen from the photos shown above, the presence of ZIF Tape greatly inhibited the formation of corrosion products.

related content

Click here for the ZIF Tape brochure

For more information about Zerust® Inhibitor Fusion (ZIF) Tape, please contact us.