Calculating VCI for Optimal Application Performance on Aboveground Storage Tank Bottoms

OVERVIEW

Proper calculations can make a huge difference in the performance of a Vapor Corrosion Inhibitor (VCI) application for Aboveground Storage Tank (AST) Bottoms.

Zerust Oil & Gas calculates based on the volume needed for a proper installation rather than just simply calculating the surface area.

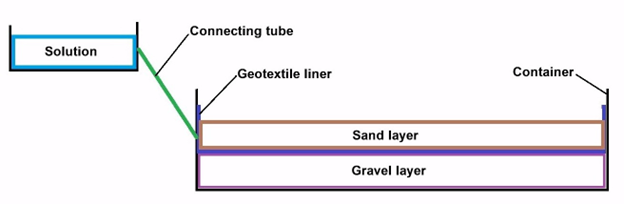

Calculating the total surface area is important to ensure you have proper coverage across the surface of an asset. Unfortunately, however, the absorption rate of the material under the surface also impacts the longevity and effectiveness of the installation.

For instance, if injected onto a sand base, gravity will cause the solution to move downward into the sand. If injecting at a slow enough rate, you will be able to evenly distribute the VCI both horizontally and vertically. If exceeding the flow rate, the excess solution will flow to the bottom of the liner, collect, and then propagate vertically by capillary action and provide protection through the sand to the asset being protected.

calculate depth & surface area

Calculating both the depth and surface area ensures a more thorough installation that will protect the asset longer and more effectively. For example, even in the worst-case scenario of a flood, there will be enough leftover material to offer a safety margin and effectively protect the assets.

Conclusion

While calculating both the depth and surface area to account for a safety margin of VCI may be more expensive up front, this equates to a lower operating cost and fewer installs over time compared to a quick, simple surface area calculation.

related content

Zerust's Corrosion Solution Process

For more information about Zerust's Corrosion Solutions, please contact us.