Defending Metal Integrity: Zerust® Zerion® FAN-6 Corrosion Inhibitor

A primary contributor to failures in Aboveground Storage Tanks (ASTs) is the structural failure of the tank bottom, with Soil Side Bottom (SSB) corrosion being a predominant factor leading to such failures. Thereby, tank bottoms need proactive measures for mitigation, and while Volatile Corrosion Inhibitors (VCIs) can extend the tank floor's lifespan by providing protection to the soil side through direct contact and in voids containing airspace, eventual replacement becomes unavoidable.

Soluble Corrosion Inhibitors (SCIs) complement the conventional VCI application by acting as contact-only inhibitors, creating an alkaline environment, and neutralizing acidic species for corrosion protection. A novel application method using Zerion FAN-6 involves applying the corrosion inhibitor directly to the tank foundation as a powder during tank downtime for replacement or new floor plate application. If the floor is already installed, ports can be added for injecting FAN-6 solution through the floor.

Zerion FAN-6, an inorganic powder, introduces a new application termed "Top Dressing," applied when the floor plates are removed. New floor plates can be installed and welded over without concerns about weld porosity caused by organic material or chemical depletion, as FAN-6 remains stable up to 851°C. This approach can be complemented by VCI application before or after the tank returns to service.

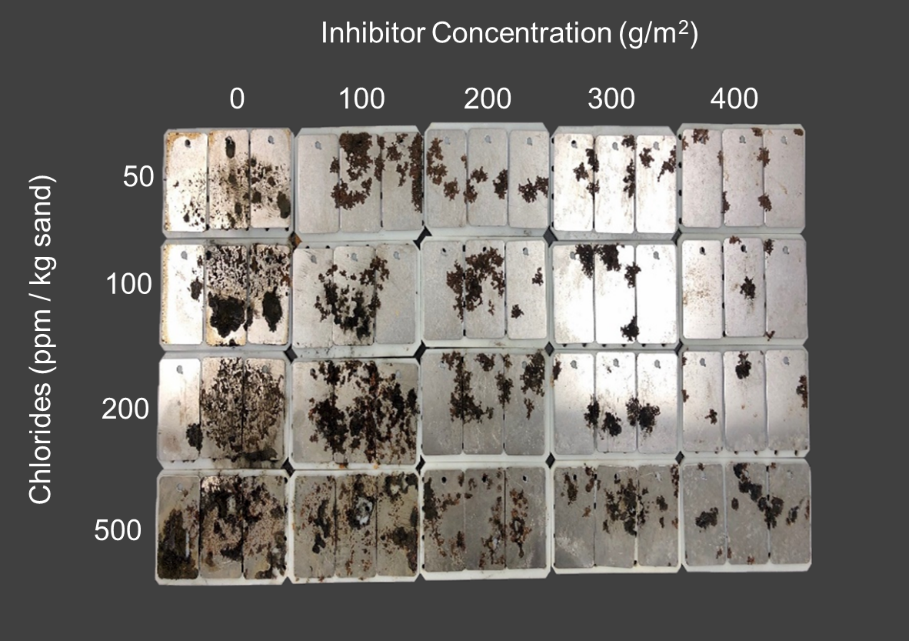

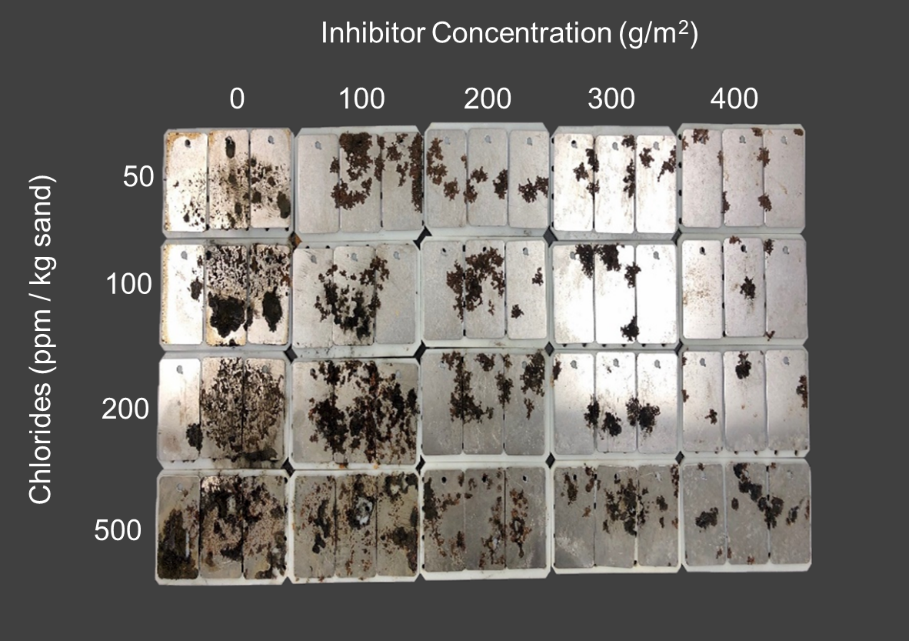

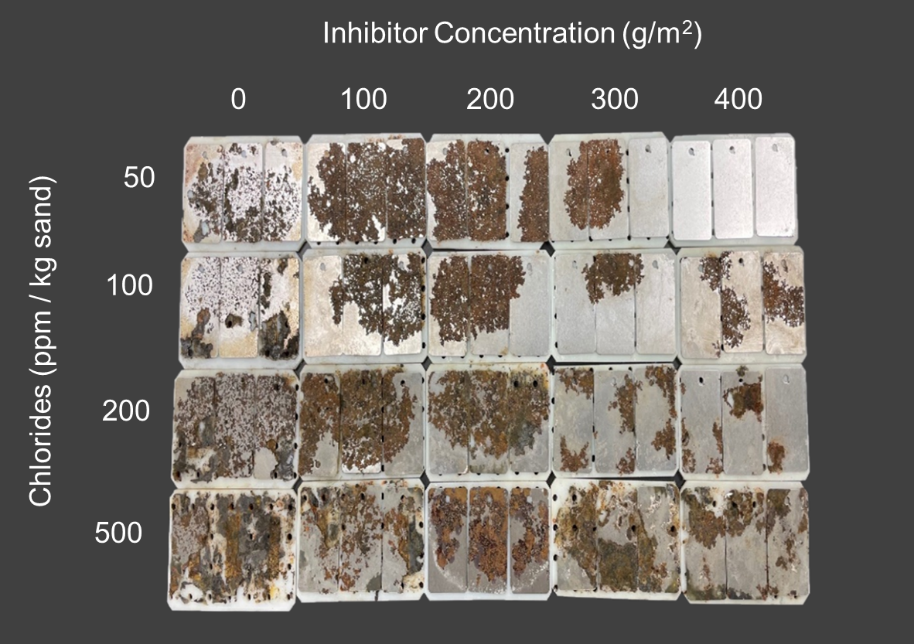

In a laboratory "Top Dress" experiment, various concentrations of Zerion® FAN-6 were assessed against different chloride contamination levels in a damp sand bed over a period of a year. The samples were aged at 40°C. Figure 1 presents the condition of the coupons after three months, while Figure 2 depicts the state of the coupons after one year. Qualitative observations indicated a correlation between the severity of the corrosion products proportional to concentration of the contamination and the duration of aging. Significantly, an increase in FAN-6 concentration demonstrated a corresponding reduction in corrosion severity. The accompanying images of test panels at three and twelve months showcase FAN-6's effectiveness against elevated chloride concentrations, highlighting a decline in corrosion severity with higher inhibitor concentration and an increase with elevated chloride contamination levels.

Figure 1: Three-Month Evaluation: Visual representation of coupons treated with varying concentrations of Zerion® FAN-6, illustrating corrosion severity in relation to chloride contamination levels.

Figure 2: One-Year Evaluation: Visual comparison of coupons subjected to different concentrations of Zerion® FAN-6, demonstrating the evolution of corrosion severity over time in response to varying chloride contamination levels.

Key Features of Zerust® Zerion® FAN-6:

- Neutralizes acidic species.

- Creates an alkaline environment.

- Versatile application: can be applied as a powder or dissolved into solution.

- Non-hazardous and environmentally friendly.

- Long-term corrosion protection.

- Economical cost.

- Protection at low concentrations.

Additional Features:

- Compatibility with Vapor Corrosion Inhibitors (VCIs).

- Concentration range: 0.5% - 10%.

- Temperature Stability: FAN-6 (stable until 851°C).

Conclusion:

Zerust® Zerion® FAN-6 offer a versatile, cost-effective, and environmentally friendly solution for protection of critical infrastructure. Click here for more product information.

Contact Zerust today and explore how Zerust® Zerion® FAN-6 can elevate the protection of your critical infrastructure.