Zerion® AutoFog® A

FLASH CORROSION INHIBITOR FOR EXPOSED METAL SURFACES

Zerust’s AutoFog A is a revolutionary Flash Corrosion Inhibitor (FCITM) that diffuses rapidly to provide corrosion protection for bare metal surfaces. The unique rapid diffusing action allows cor- rosion inhibition of pipelines, voids and other enclosed spaces without the need for power sprays or mechanical fogging of powders.

- Largest protection volume of any diffuser in its class

- Combination of FCI and phased release Zerust® VCI’s allows for long-term protection of metal assets

- Effective in the presence of acid gas contaminant

The FCI action is especially important when welding shut voids and in enclosed spaces where sweating due to trapped humidity inside the void can cause immediate corrosion.

Applications

AutoFog A is ideally suited for the prevention of corrosion in large metal voids and enclosures. With its high diffusion rate, AutoFog is especially effective in enclosures containing pipes, interstices, recesses, etc. which are difficult to access or protect. In many situations, AutoFog is an inexpensive and easy-to-implement alternative to nitrogen purging, eliminating the need for pressurization or continuous monitoring.

Typical applications include the following:

- Mothballing of Process Equipment

- Heat exchangers

- Boilers

- Sulfur recovery units

- Generators

- Turbines

- Pipeline racks

Protection of Sealed Spaces

- Floating roof tank pontoons

- Offshore platform legs

- Ship blocks

Product Use

Voids and Enclosed Spaces:

AutoFog® diffusers can be placed inside a void or enclosure before it is welded shut or sealed. They can be fixed in place with a wire mesh basket for easy retrieval and replacement. In certain applications the diffuser packaging may be slit and the Zerion® powder poured into the void to provide protection.

Asset Preservation:

The asset to be preserved should first be cleaned and then enclosed. The enclosure could be either a containment packaging of Zerust® corrosion inhibitor film or an integral self-sealing piece of equipment. AutoFog diffusers are then placed inside the void or enclosure before it is sealed.

Protection Type

Ferrous and aluminum protection.

Protects yellow metals when used as instructed.

Do not place in direct contact with copper or brass and test before use.

Product Properties

pH: > 8-10 for 1% solution Odor: Amine-like

Appearance: Light tan, off-white powder.

Packaging: Breathable sachet contained in an outer leakproof bag.

Safety & Handling

Avoid contact with eyes and skin through use of safety glasses and gloves.

Use a dust mask to prevent inhalation.

See safety data sheet for more information.

Storage

Shelf life is 24 months.

Store in a sealed container in a dry, ventilated warehouse without exposure to direct sunlight and temperature below 85oF (29oC).

Benefits

Fast-acting corrosion protection.

Easy-to-use, with no need for additional mechanical fogging equipment.

Quick/simple installation and removal with minimal training.

Inexpensive solution for aggressive environments. Highly effective and unique.

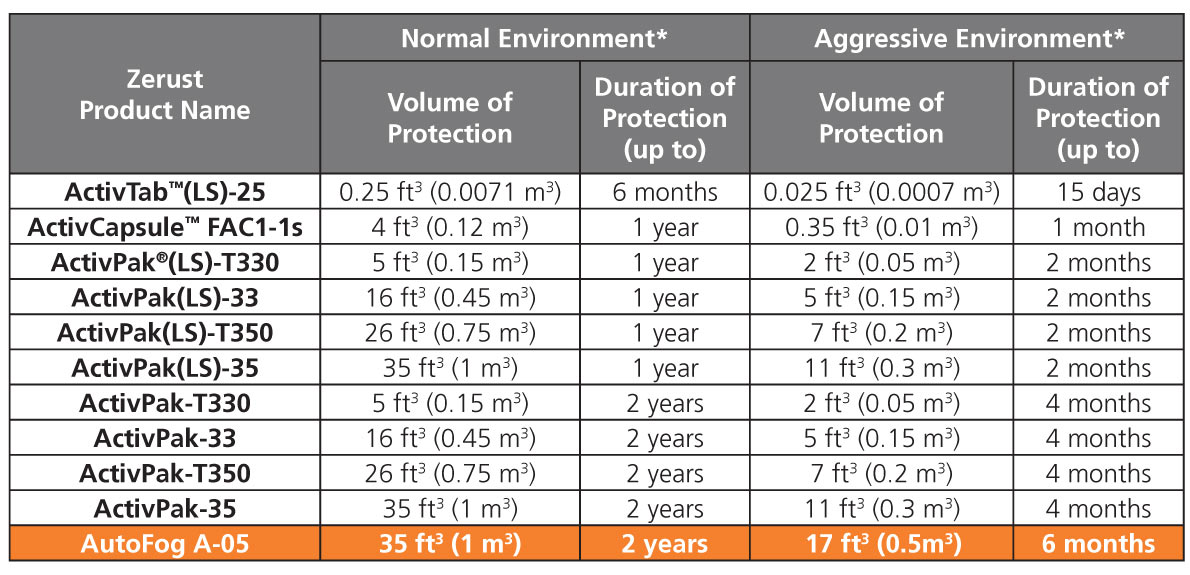

Product Sizes & Specifications

*Normal Environment defined as having 1 ppm of SO2 or less with minimal salts - typically found in light industrial areas, warehouses and coastal facilities. Aggressive Environment defined as having between 1 ppm and 4.5 ppm of SO2 with a high salt content – typically found in/around refineries, oil production areas, wastewater treatment facilities, pulp and paper plants and most coastal facilities.

How to Use in Shipment and Storage

1. Determine the correct number of AutoFog packets needed to protect intended space. Do not overload protection.

2. Remove from plastic packaging, but do not puncture product sachet. Punctured sachets may result in a dust hazard.

3. Place packet nearest to the center of the space as possible. If using multiple packets, distribute them evenly. Direct contact with ferrous metals is ok. Do not place in direct contact with yellow metals (brass, copper, zinc).

4. Seal package or enclosure to contain vapor corrosion inhibitors inside.